Automation Intern

Singapore, Singapore Job ID R0170801 Category Early Career Subcategory Interns, trainees, apprentices,Interns, trainees, apprentices Business Unit Global Manufacturing & Supply Job Type Full timeBy clicking the “Apply” button, I understand that my employment application process with Takeda will commence and that the information I provide in my application will be processed in line with Takeda’s Privacy Notice and Terms of Use. I further attest that all information I submit in my employment application is true to the best of my knowledge.

Job Description

Primary Objectives of this Job

The Automation Intern will participate in a structured 12-month rotational program within the Takeda Singapore Manufacturing facility to gain practical experience in biopharmaceutical manufacturing automation.

The primary purpose of this role is to deliver scoped projects and support troubleshooting, validation and documentation activities as well as to contribute to continuous improvement initiatives.

The Automation intern shall build foundational knowledge in GMP, EHS, and data integrity standards as well as to develop technical competencies in process automation systems and related OT platforms.

This role is designed to prepare the intern for a future position as a junior automation engineer by providing hands-on exposure to engineering, manufacturing, and automation functions in a regulated environment.

Responsibilities

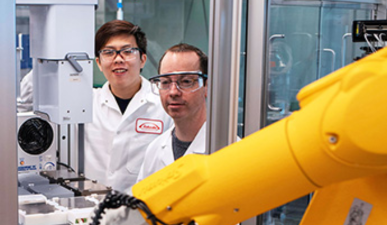

- Participate in a 12-month rotational program (3 months with Site Engineering Department, 3 months with Manufacturing and 6 months with Automation Function)

- Gain overview of manufacturing processes and perform simple hands-on operations in manufacturing suites.

- Complete mandatory SOP and training modules as per program matrix.

- Deliver scoped projects such as CSV workflow improvements, alarm rationalization, user intervention reduction, data integrity and cyber security remediations, culminating in a capstone automation project including preparation of reports, documentations and presentations.

- Support troubleshooting, validation, and documentation activities under close supervision, ensuring compliance with regulatory and quality requirements.

- Participate in commissioning and qualification activities involving Automation systems.

- Participate actively and contribute to continuous improvement initiatives that enhance operational reliability, safety, and efficiency.

- Implementing simple changes or modifications.

- Be rotated to Manufacturing for a period of 3 months to take on a Biotechnologist role working in a Rotating 12-hour shift pattern.

- Responsibility to adhere to any applicable EHS requirements.

- Commitment to a fair and respectful relationship to others and behavior in accordance with Takeda’s Code of Conduct.

- Any other duties as assigned by supervisor.

Education and Experience Requirements

- Final year diploma/degree undergraduate in Biological Engineering, Electrical, Computing, Mechatronic Engineering or Pharmaceutical Engineering.

- Strong interest in biopharmaceutical manufacturing and process automation.

- Familiarity with basic engineering principles; prior internship experience is an added advantage

Key Skills and Competencies

- Strong knowledge with engineering principles

- Analytical thinking and problem-solving skills.

- Strong communication and teamwork abilities.

- Willingness to learn and adapt in a regulated environment