Extended Reality: Changing How We Work

Extended Reality (XR): Experiencing is believing

The pandemic has brought substantial changes to our lives, including an acceleration of digital transformation, and especially collaboration across distances.

Extended Reality (XR), which comprises Augmented Mixed and Virtual Reality, has the potential to transform the way we interact drastically. It also generates numerous benefits, such as time savings, right-first- time, training effectiveness, as well as confidence and fun.

At Takeda, we are applying XR to support our teams in Global Manufacturing & Supply and Global Quality (GMS/GQ). Read how below!

Remote Assist

In GMS/GQ, XR technology is used mainly for remote assistance, which enables employees to collaborate more efficiently by working together from different locations. It provides reliable live connection via video call between operational workers on the shop floor or lab and experts who are not onsite. Participants can use mixed reality annotations and headsets (such as HoloLens) to support their call.

Remote assist call with a virtual screen in Osaka Digital Instructions

Digital Instructions

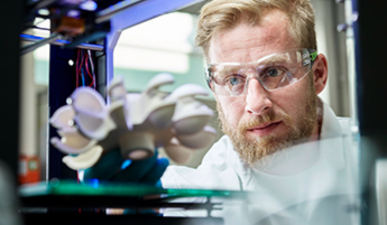

Another application of XR technology is Digital Instructions, which explains the best way to complete a specific procedure. Digital Instructions translates procedures into a human-centric way of working, which allows any employee on the shop floor to complete the task at hand. It contains pictures and videos, sometimes even 3D holograms anchored in relevant areas.

With a pilot community in Osaka, Singapore and Vienna, the Digital and Data Science team is collaborating with other global functions to define fitting processes to further use Digital Instructions in GxP environments.

A digital instruction being designed in Singapore

What will the future bring?

We’re expecting the integration of XR technologies with other systems, as well as the possibility to exchange data live and record relevant information. In the meantime, we aim to facilitate XR’s daily use and create a community of early adaptors - because experiencing is believing and believing is the foundation for successful collaboration.

Jobs for you

- Logistics Operations Excellence Intern Zurich, Switzerland Category: Interns, trainees, apprentices

- Commercial Quality Senior Specialist / Deputy Responsible Person - Poland Warsaw, Poland Category: Quality

- Senior Operational Excellence Champion - Lean Black Belt Neuchâtel, Switzerland Category: Project/Process Management

- Manufacturing Associate l Brooklyn Park, Minnesota Category: Manufacturing/Production